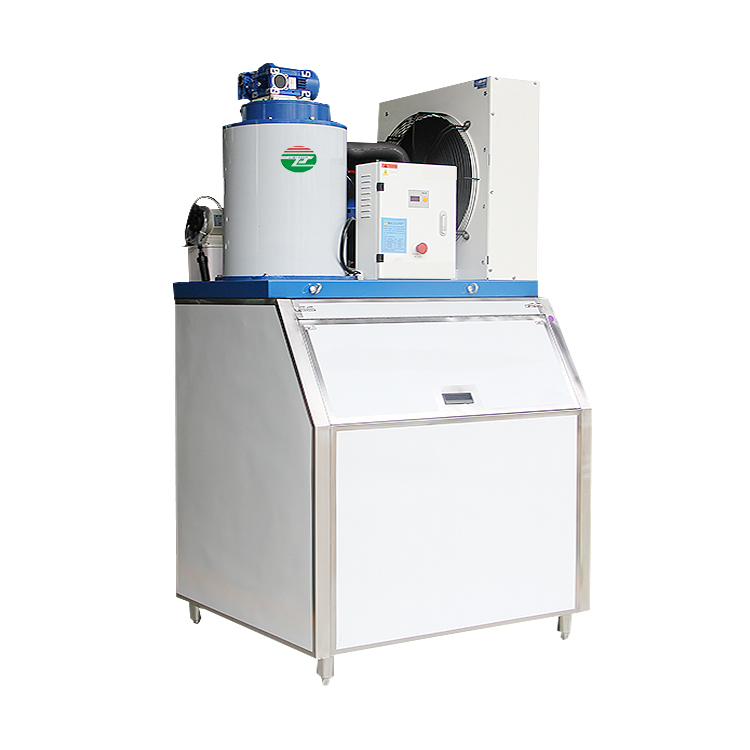

- Commercial 300kg Ice Tube Maker Machine

- Get A Quote

Xiamen Jialiang ice machine is widely used in supermarket preservation, seafood restaurant, food processing, fruit and vegetable preservation, chemical manufacturing, biotechnology, wine industry and mine cooling.

- Description

- Features

Product Description

Product Type

The ice maker is a kind of refrigeration mechanical equipment, which produces ice cubes after the water is cooled by the refrigerant of the refrigeration system through the evaporator. According to the principle and production method of the evaporator, the shapes of the generated ice cubes are also different; people generally divide the ice maker into flake ice machine, plate ice machine, tube ice machine, block ice machine and so on according to the shape of ice.

| Product Name | Ice Machine |

| Capacity | 300kg/24h, 500kg/24h, 1 ton/24h, 2 tons/24h, 3 tons/24h, 4 tons/24h 5 tons/24h, 6 tons/24h, 8 tons/24h, 10 tons/24h, 12 tons/24h, 15 tons/24h, 40 tons/24h |

| After Warranty Service | Video Technical Support, Online Support |

| Ice Thickness | 1.8~2.5mm |

| Refrigerant | R404A |

| Machine Material | SS304 tube, SS304 framework, compressor, condenser, valve, etc. |

| Applicable Industries | Food & Beverage Factory, Restaurant, Food Shop, Energy & Mining, Food & Beverage Shops |

| Cooling Type | Air Cooling/Water Cooling |

Ice machines are divided by the shape of ice: flake ice, plate ice, tube ice, block ice, etc.

Ice-making methods are divided into spray type, flow type and immersion type.

Refrigeration methods can be divided into: water-cooled ice machine, air-cooled ice machine.

Features:

1.Internally-scraping ice skate can help reduce energy consumption and prevent leakage of refrigerant

2.Stainless steel materials , advanced processing equipment and heat treatment ensure the best heat transfer efficiency

3.The design of the large water receiving plate can prevent water leaking at the bottom of drum

4.Photoelectric switch is directly installed in bottom of evaporator

5.Direct liquid feeding and dry evaporation --simple , safe and reliable control

6.Integrated modular equipment installation is convenient for maintenance

Application Scenarios

1. Application in aquatic product processing: It can reduce the temperature of processing medium, cleaning water and aquatic products, prevent bacterial growth, and maintain the freshness of aquatic products during processing.

2. Application of meat processing technology: Mix the flake ice that meets the hygienic standard into the meat and stir. In order to achieve the purpose of cooling and preservation.

3. Application in food processing: For example, when stirring or adding cream in bread production, use ice making to quickly cool to prevent fermentation.

4. Application of vegetable processing: Ice making is used for harvesting and processing of agricultural products and vegetables to reduce the metabolism of agricultural products and the growth rate of bacteria. Extend the shelf life of produce and vegetables.

5. Application in long-distance transportation: It is more and more widely used for long-distance transportation of products that need to be refrigerated and fresh, such as ocean fishing and vegetable transportation.

6. It is also widely used in laboratories, medicine, chemical industry, artificial ski resorts and other industries.

Factory Tour

Ice Factory

Our ice machines are sold all over the world with their high quality materials and competitive prices. Generally, we provide customers with three types of ice machines: commercial ice machines, home ice machines, and industrial ice machines.

1. Reply your enquire in 24 working hours.

2. Experienced staffs are able to answer all your questions in profesional and fluent English.

3. Exclusive and unique solution can be provided to our customer by our well-trained and professional engineers and staffs.

4. Different kind of customized ice machines are available.

5. Supply the ice machine of high quality.

Packaging and Shipping

Packaging:

1. Standard wooden case.

2. Completely ice machine contain: machine, cover,cooling tower, water pump, water pipes and water pipe fittings.

3. Machine come into use, customer only need prepare power for the machine.

4. All required components for installing the machine will be provided.

5. Our factory also can produce cold room for store ice.

Contact Us

Company Name: Xiamen Jialiang Refrigeration Equipment Co., Ltd.

Operational Address: 501-6, No. 8, Huli Avenue, Xiamen, Fujian, China

E-mail: jialiang@coldroomchina.com

WhatsApp/ Wechat: +86-159-5926-9660

Tel: +86-592-5107173 Fax: +86-592-5332513