Customized cold storage solutions: meeting specific industry needs

In today's rapidly evolving business landscape, it is crucial for companies to find innovative solutions that cater to their specific industry needs. One such solution that has gained significant traction is customized cold storage. This article explores the concept of customized cold storage solutions and how they can meet the unique requirements of various industries.

The first section delves into the importance of understanding specific industry needs. Each industry has its own set of challenges and requirements when it comes to storing perishable goods. By gaining a deep understanding of these needs, companies can design and implement cold storage solutions that address their specific pain points and maximize efficiency.

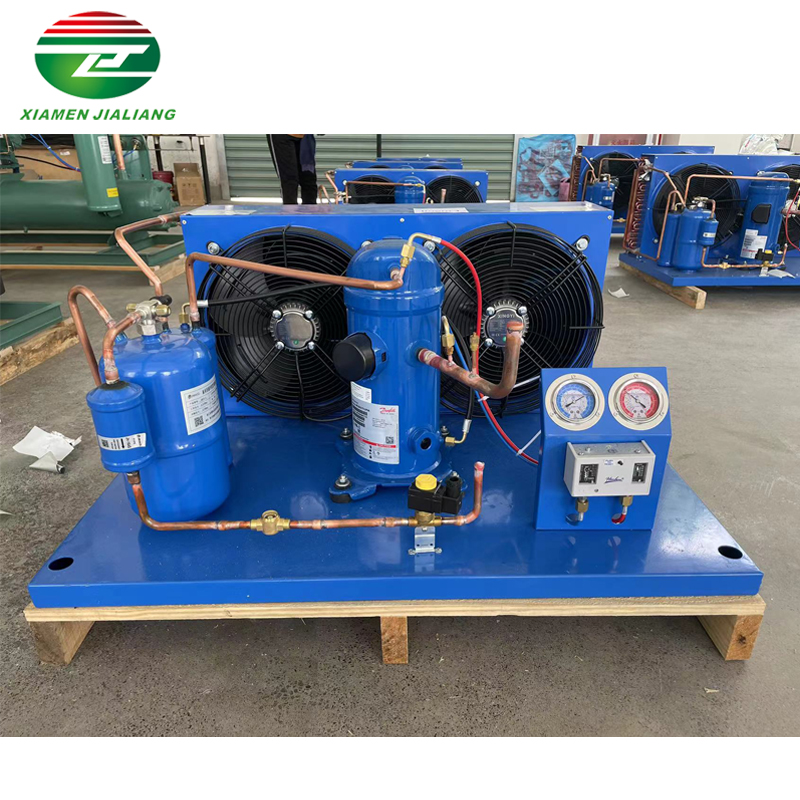

The next section highlights the benefits of customized cold storage solutions. One size does not fit all when it comes to cold storage, and off-the-shelf solutions often fall short in meeting industry-specific demands. Customization allows companies to optimize storage space, ensure optimal temperature control, and streamline logistics, ultimately leading to cost savings and improved customer satisfaction.

Tailoring cold storage solutions to industry requirements is the focal point of the following section. By taking into consideration factors such as the type of products being stored, storage capacity, and handling processes, businesses can create bespoke solutions that align with their unique needs. This tailored approach minimizes wastage, reduces the risk of product spoilage, and enhances overall supply chain efficiency.

Finally, the article concludes with a series of compelling case studies that showcase successful implementations of customized cold storage solutions. These real-world examples demonstrate how companies from various industries have leveraged customized solutions to overcome their specific challenges and achieve tangible business outcomes.

In summary, customized cold storage solutions offer a tailored approach to meet the specific needs of different industries. By understanding industry requirements, reaping the benefits of customization, and tailoring solutions accordingly, companies can optimize their cold storage operations and gain a competitive edge in the market.

Understanding the Specific Industry Needs

Understanding the specific industry needs is crucial for the success of any business. In today's competitive market, businesses need to adapt to the changing needs and demands of their target audience. One such industry with unique requirements is the cold room industry.

Cold rooms play a vital role in various sectors, including food storage, pharmaceuticals, and research laboratories. These specialized rooms are designed to maintain low temperatures for the preservation and storage of perishable goods. Understanding the specific needs of this industry is essential to ensure the efficient and effective operation of cold rooms.

One of the primary considerations in the cold room industry is temperature control. Maintaining the desired temperature is crucial for preserving the quality and integrity of the stored goods. Cold rooms are equipped with advanced temperature control systems that allow for precise regulation of temperatures. This ensures that perishable items, such as food or vaccines, are kept at the optimal conditions to prevent spoilage or degradation.

Another important aspect of cold room industry needs is insulation. Proper insulation is necessary to prevent heat transfer from the external environment to the interior of the cold room. This is achieved through the use of high-quality insulation materials, such as polyurethane foam or fiberglass. Insulation plays a crucial role in maintaining the desired temperature inside the cold room and reducing energy consumption.

Furthermore, cold rooms also require effective ventilation systems. Ventilation helps in maintaining air circulation and preventing the buildup of moisture or odors inside the room. It is essential to have a well-designed ventilation system that can efficiently remove excess heat and humidity. This helps to prevent the growth of mold or bacteria, which can adversely affect the stored goods.

In addition to temperature control, insulation, and ventilation, cold rooms also require robust security measures. These rooms often store valuable or sensitive items, making security a top priority. Access control systems, surveillance cameras, and alarms are commonly used to ensure the safety and integrity of the stored goods.

Understanding the specific needs of the cold room industry is vital for businesses operating in this sector. By addressing these needs, companies can provide reliable and efficient cold room solutions to their clients. Whether it is designing, constructing, or maintaining cold rooms, a thorough understanding of the industry requirements is essential for success.

Benefits of Customized Cold Storage Solutions

Cold storage plays a crucial role in various industries, especially those involved in the storage and preservation of perishable goods. With the advancement of technology, businesses now have the option to invest in customized cold storage solutions that cater to their specific needs. These customized cold storage solutions offer numerous benefits that can significantly impact the efficiency and profitability of a business.

One of the key benefits of customized cold storage solutions is the ability to optimize space utilization. Each business has its own unique requirements and storage capacity needs. With customized solutions, businesses can design cold rooms that maximize the available space, allowing for efficient storage of goods. This not only ensures optimal utilization of the available area but also enables businesses to store a larger quantity of goods within a limited space.

Another advantage of customized cold storage solutions is enhanced temperature control. Different products require specific temperature levels for preservation. With customized cold rooms, businesses can set and maintain the desired temperature range, ensuring that the stored goods remain fresh and unaffected by external conditions. This precise temperature control helps in extending the shelf life of perishable items, reducing wastage, and ultimately saving costs for the business.

Furthermore, customized cold storage solutions offer improved energy efficiency. Cold rooms are energy-intensive, and traditional cold storage systems often consume a significant amount of energy. However, with customized solutions, businesses can incorporate energy-efficient technologies and equipment, such as advanced insulation materials, energy-saving refrigeration systems, and smart temperature monitoring systems. These features contribute to reduced energy consumption, leading to cost savings and a more sustainable operation.

In addition to space utilization, temperature control, and energy efficiency, customized cold storage solutions also provide businesses with the flexibility to adapt to changing needs. As businesses grow and evolve, their storage requirements may change as well. Customized solutions allow for easy modification and expansion of cold rooms to accommodate increased storage needs or changes in product types. This flexibility ensures that businesses can continue to meet their storage requirements without disruptions or the need for major investments in new infrastructure.

Tailoring Cold Storage Solutions to Industry Requirements

When it comes to cold storage solutions, tailoring them to meet industry requirements is essential. Whether it's the pharmaceutical industry, food and beverage sector, or any other industry that relies on cold room facilities, having the right storage solution is crucial for maintaining the quality and integrity of products.

Cold rooms play a vital role in preserving perishable goods, such as vaccines, drugs, and food items. The temperature-controlled environment provided by these rooms ensures that products are kept at the optimal temperature to prevent spoilage and maintain their efficacy. However, not all cold storage solutions are created equal, and different industries have specific requirements that must be met.

For the pharmaceutical industry, cold rooms are designed to meet stringent regulations and standards. These rooms must maintain precise temperature ranges to ensure the stability of drugs and vaccines. Additionally, they need to have proper ventilation and air filtration systems to prevent cross-contamination and maintain a sterile environment. The storage shelves and racks should also be designed to store pharmaceutical products safely and efficiently.

In the food and beverage industry, cold storage solutions need to be tailored to the specific needs of different products. For example, fresh produce requires different temperature and humidity levels compared to dairy products or frozen goods. The design of cold rooms should take into account factors such as airflow, insulation, and shelving configuration to ensure optimal storage conditions for each type of product. Additionally, proper labeling and organization systems are crucial to prevent mix-ups and ensure efficient inventory management.

Tailoring cold storage solutions to industry requirements also involves considering the scalability and future growth of businesses. As industries evolve and expand, storage needs may increase. Therefore, it is essential to design cold rooms that can accommodate future growth and be easily modified or expanded as needed.

Case Studies: Successful Implementation

In the realm of business, success stories are often shared and celebrated. Case studies serve as a testament to the effectiveness of strategies and the ability to achieve goals. One particular area where successful implementation plays a pivotal role is in the realm of cold rooms.

Cold rooms are essential for businesses that require specialized temperature-controlled environments. From food storage to pharmaceuticals, these rooms provide crucial support in preserving the quality and integrity of various products. Implementing a cold room successfully requires careful planning, meticulous execution, and a deep understanding of the specific industry requirements.

One notable case study revolves around a pharmaceutical company that sought to upgrade its cold room facilities. The company recognized the importance of maintaining optimal temperature conditions for its sensitive products, as any deviation could lead to compromised efficacy and potential financial losses. With the objective of enhancing efficiency and ensuring regulatory compliance, the company embarked on an ambitious implementation plan.

The first step involved conducting a comprehensive assessment of the existing cold room infrastructure. This evaluation helped identify areas that required improvement, such as insulation, cooling systems, and temperature monitoring mechanisms. By addressing these issues, the company aimed to create a more robust and reliable environment for its valuable pharmaceutical inventory.

Next, a team of experts was assembled to execute the necessary upgrades. This team consisted of engineers, technicians, and project managers who possessed extensive knowledge and experience in cold room installations. Their expertise ensured that the implementation process adhered to industry standards and best practices.

During the implementation phase, meticulous attention was paid to every detail. The insulation was upgraded to minimize heat transfer, while the cooling systems were optimized to maintain consistent temperatures. Additionally, advanced monitoring systems were installed to provide real-time data on temperature fluctuations and alert the relevant personnel in case of any anomalies.

The successful implementation of the upgraded cold room infrastructure yielded significant benefits for the pharmaceutical company. Product quality was safeguarded, ensuring that medications remained potent and effective. Moreover, the company experienced improved operational efficiency, as the upgraded systems required less energy and maintenance.

Conclusion

The article emphasizes the importance of understanding and addressing the specific needs of the cold room industry for efficient operation of specialized storage facilities. Temperature control, insulation, ventilation, and security are crucial aspects that need to be considered. Customized cold storage solutions offer benefits such as optimized space utilization, precise temperature control, energy efficiency, and preservation of perishable goods. Businesses can enhance operational efficiency, reduce costs, and ensure the quality and freshness of their stored products by investing in tailored cold storage solutions. Cold storage solutions are not one-size-fits-all and must be tailored to specific needs of industries like pharmaceuticals and food and beverage. Successful implementation of customized cold storage solutions leads to enhanced product quality, operational efficiency, and overall business performance.