Cold Room Insulated Panels, Materials and Considerations

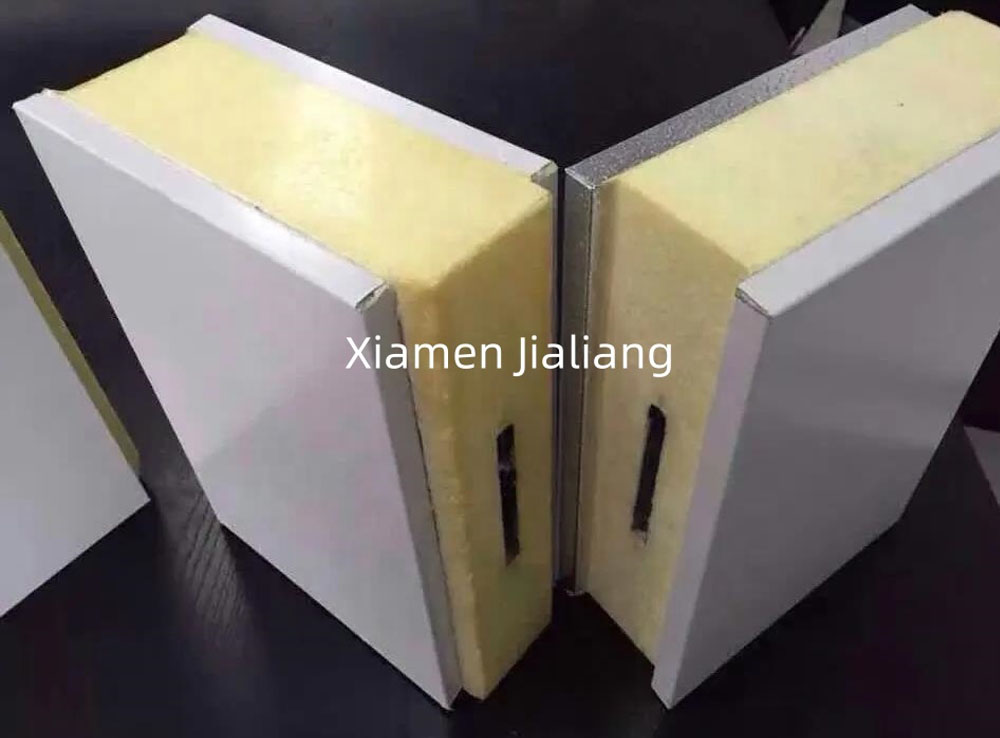

Composed of the core layer between two structural plates

Cold Room Insulated Panels, Materials and Considerations

How Are Cold rooms Insulated?

Cold rooms are essential for businesses that handle perishable products. These businesses are involved in food manufacturing and storage, pharmaceutical manufacturing and storage, laboratory testing, medical and veterinary science, organ storage, morgues and mortuaries. Therefore, proper cold rooms insulation can ensure that these businesses can safely store their products, whatever they may be.

Xiamen Jialiang is a limited company specializing in refrigeration equipment, which has been enjoying a high reputation in the field of refrigeration products and equipment since 1999. This guide will cover everything you need to know about cold rooms insulation.

Types of Insulated Panels for Cold Rooms

Insulation panels, a building material that can maintain the temperature in a cold room and prevent cold air from leaking. It consists of a core layer between two structural boards. They are durable and require less timber than standard construction.

Common types of insulated panels include:

Expanded Polystyrene Insulated Panels

Neopor Insulated Panels

Polyurethane Insulated Panels

Compressed Straw Core Insulated Panels

The structural boards are typically either plywood or cement.

Cold Room Design Considerations

How cold you intend to keep the room, the weight of the products you need to store, external heat exposure, foot traffic inside and other factors will all determine the thickness of your insulated panels.

Insulated panels can be used in the construction of external walls, floors and roofs, and these design factors can also affect the material and thickness of the insulated panels used.

First, we have the interlocking walls of the freezer. These floor-to-ceiling walls enclose the cold room. Sometimes one of these walls is a large door. Sometimes the door is just a normal door built into one of the walls. The panels on these walls are designed to eliminate potential gaps to prevent cold air from leaking.

Next, we come to the floor. Floors often require additional insulation to prevent heat transfer from the surface, especially if people are moving about the room frequently.

Finally, there's the roof. The roof will either be exposed to direct sunlight or foot traffic from the floor above. Therefore, it also requires additional insulation.

Characteristics of a Thermal Insulation System

Now that you know the elements of cold rooms, you have to consider what constitutes a quality insulation material. Your insulated panels should meet the following requirements:

Have a minimum R-value(thermal resistance value) of up to 40 to ensure high heat insulation efficiency.

The thickness is between 5cm and 30cm.

Completely sealed to avoid cold air leakage and prevent the entry of bacteria and dust.

It has high compressive strength and can withstand being under the floor.

Custom Cold Rooms Designed for Your Needs

At Xiamen Jialiang, we attach great importance to the design of cold rooms. We know you will entrust us to professionally design, install and maintain your cold room according to the products you need to store. Our cold room is constructed to the highest standards. Please put your confidence in Xiamen Jialiang, the most trusted commercial refrigeration specialist in China.

If you want to know more information, please consult us. https://www.coldroomchina.com